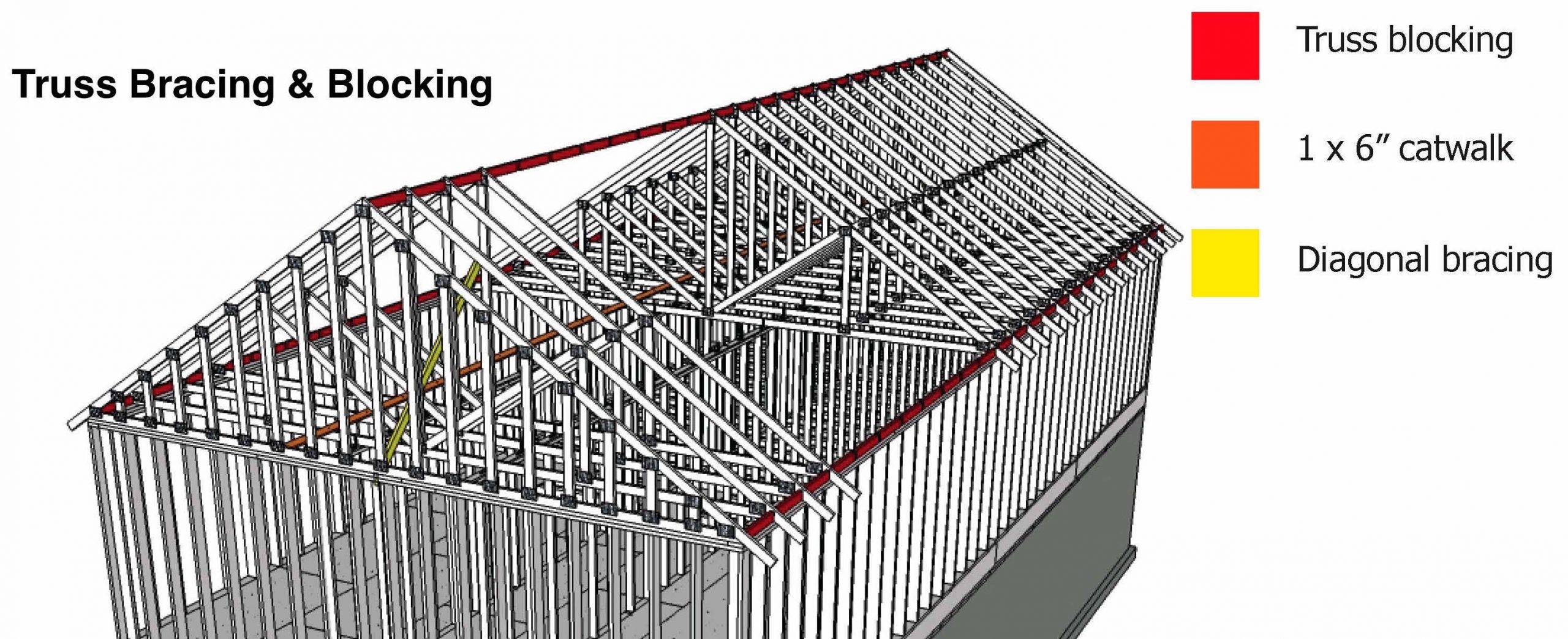

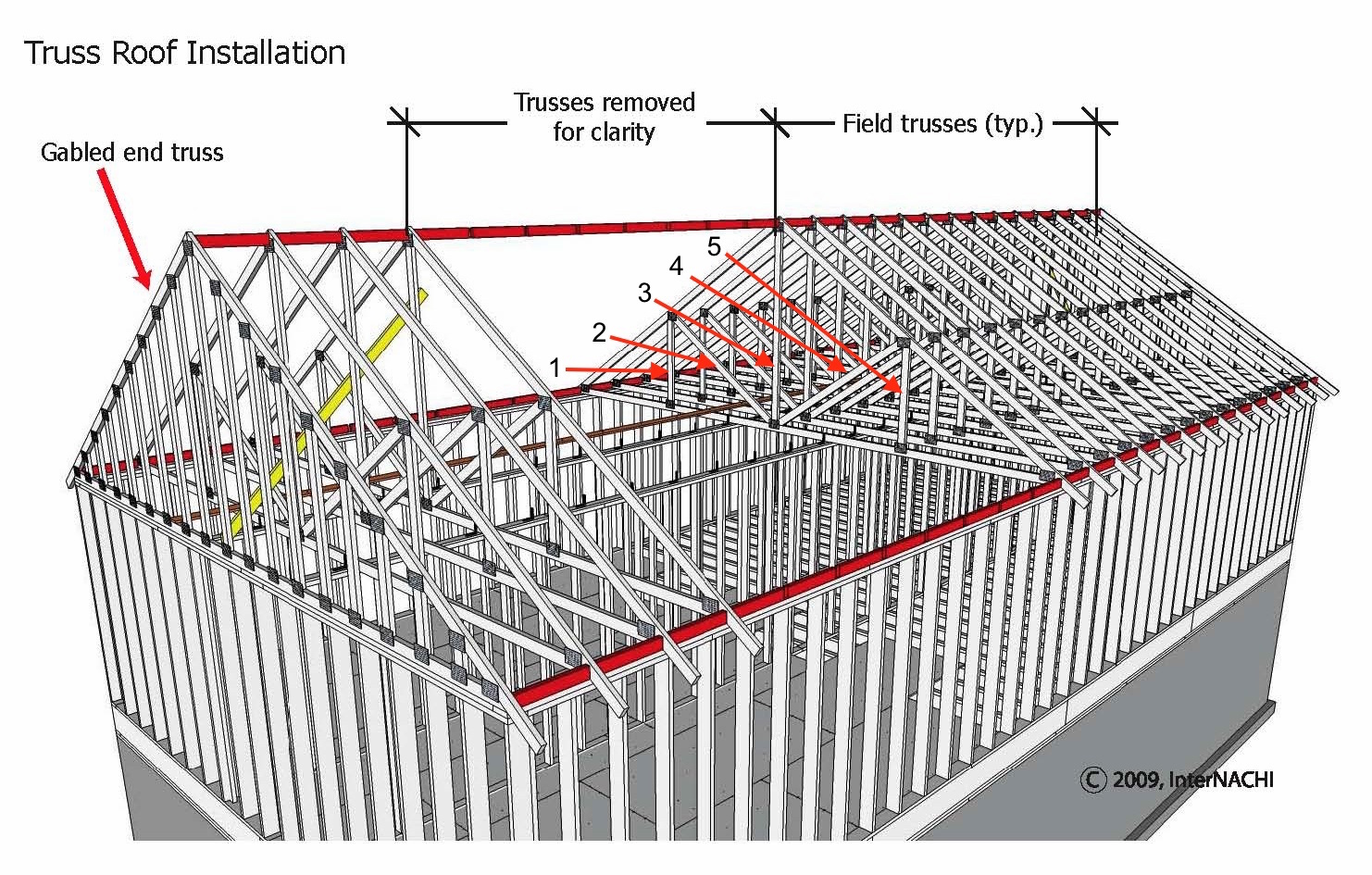

The images above and below show typical blocking and brace locations.

Ridge blocks aren't always installed, they're more commonly seen in areas with significant seismic activity.

Catwalk is nailed to the tops of the truss bottom chords to help keep them on layout (proper spacing).

Diagonal braces are typically installed as trusses are first stood into place (starting at the gabled end) to stabilize the trusses until sheathing is installed. They are left in place.

Truss braces are installed longitudinally, parallel to the ridge .

Common 2x4 brace locations:

- Braces 1&5- along intermediate vertical web members;

- Braces 2&4- along diagonal web members; and

- Brace 3- along the central vertical web member.

NOTE: Brace locations are specified by the truss roof designer and without the truss plans inspectors will have no way of verifying correct brace installation. Some homes may have very few, and similar homes may have many.

Inspection concerns

Watch for the following in truss roofs:

- Cut/damaged/altered trusses;

- Site-built (un-engineered) trusses (SE);

- Bottom chords should be clipped- not nailed- to interior walls;

- Installed plumb/near plumb;

- Over-panned (installed too far apart (standard is 24" on center);

- Too long or short

- Distortion from improper long-term storage;

- DO NOT identify missing bracing as a defect. Bracing is specified by the truss designer and requirements vary with the roof design. Some roof truss systems have little or no bracing.

Site-built Trusses:

Site-built trusses are those that have been designed by non-professionals and assembled at the jobsite. Manufactured trusses are designed by engineers and assembled in a facility before being trucked to the jobsite. Even if they are very common in the area in which you inspect, because they have not been engineered, site-built trusses may not be able to support the loads to which they will be exposed. Always recommend that they be evaluated by a structural engineer.

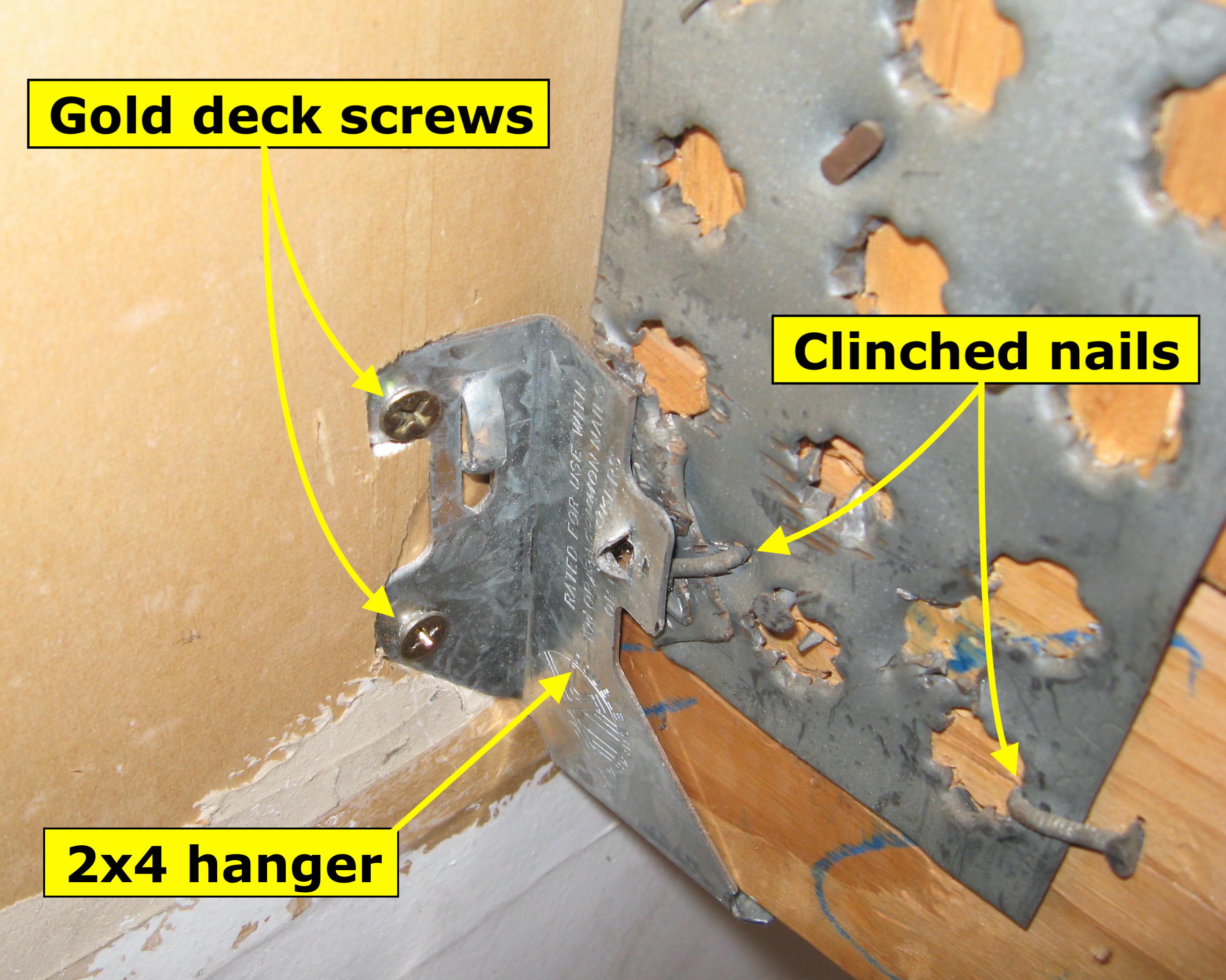

The photo above shows manufactured trusses that have been altered. Originally designed to span across the entire building, the left side has been cut off to fit against the wall. The metal truss places have bee replaced with plywood gussets. The bottom chords were improperly connected to the wall.

The 2x4 hangers were severely undersized for this application.

Gold deck screws are designed to resist withdrawal and are very weak in shear.

The truss plates had been cut, had become partially detached, and were reattached with clinched nails

NOTE: Located in Colorado, this garage was one in a long row of connected garages. The trusses in all had been cut just like these. The roof of the next garage had collapsed under a snow.load.

Truss Plates

The photo on the left shows intact truss plates connecting truss members. The photo on the right shows a truss plate that has pulled loose from the bottom chord. This is most likely to happen during installation.

Metal Connectors and their Fasteners:

- Fasteners for almost all single metal connectors will be minimum 10d nails with the number marked on the nailhead (not 8D).

- When hangers do not support top chords, i-joists require web stiffeners to be installed.

- The Simpson Strong Tie catalogue for framing connectors lists fastening requirement for most connectors you're likely to encounter.